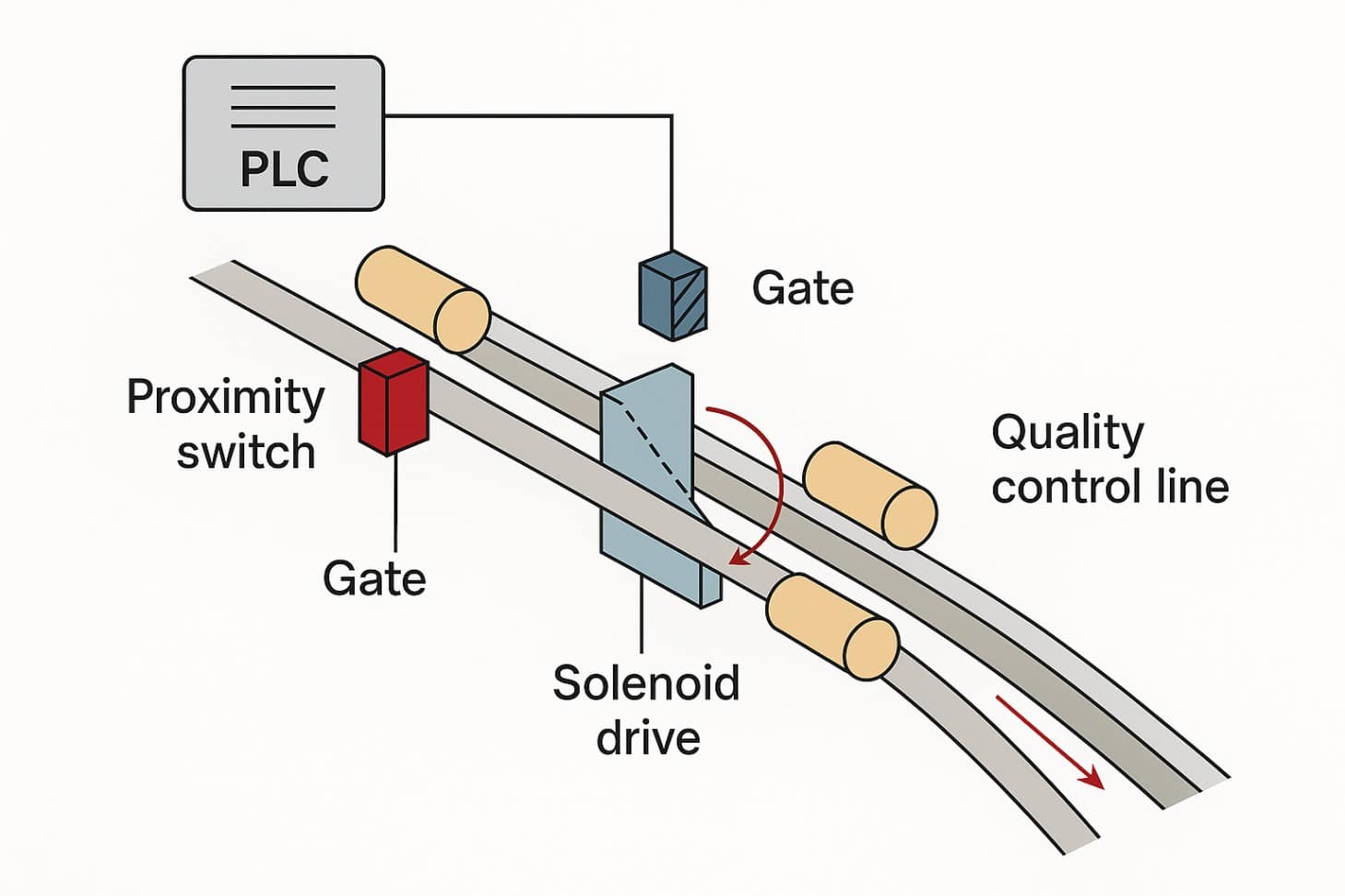

At TGEP, we specialize in delivering turnkey industrial automation solutions—from FANUC robot integration to motor control and PLC programming. One of the most effective ways to streamline material handling systems is by integrating solenoid gate drives with PLC-controlled conveyor systems, using proximity switches for precise object detection and flow control.

In this blog, we’ll break down how this setup works, why it’s beneficial, and how TGEP’s licensed electricians implement it in real-world applications.

What Is a Solenoid Gate Drive?

A solenoid gate drive is an electromechanical actuator that controls the opening and closing of gates on a conveyor system. When energized, the solenoid moves a plunger that either opens or closes a gate, allowing or stopping the flow of materials.

Why Use a PLC with a Solenoid Gate?

Programmable Logic Controllers (PLCs) are the brains behind modern automation. When paired with a solenoid gate, a PLC can:

- Control gate timing based on sensor input

- Coordinate with other devices like motors and robots

- Enable remote diagnostics and monitoring

- Improve safety and reduce manual intervention

Role of Proximity Switches

Proximity switches detect the presence of objects without physical contact. In a conveyor system, they’re typically used to:

- Detect incoming products

- Trigger the solenoid gate to open or close

- Provide feedback to the PLC for real-time decision-making

Real-World Application: TGEP Conveyor System Integration

Here’s how TGEP typically integrates these components:

1. Installation of Proximity Sensors

We mount inductive or photoelectric proximity switches at strategic points along the conveyor to detect product presence.

2. PLC Programming

Our electricians program the PLC (Allen-Bradley, Siemens, or others) to:

- Read sensor input

- Activate the solenoid gate

- Coordinate with other systems like FANUC robots or motor drives

3. Solenoid Gate Wiring

The solenoid is wired to a PLC output module. When the PLC receives a signal from the proximity switch, it energizes the solenoid to open or close the gate.

4. Testing and Commissioning

We run simulations and live tests to ensure:

- Accurate object detection

- Timely gate actuation

- Seamless integration with upstream and downstream equipment

Benefits of This Setup

✅ Improved Throughput – Automated gating reduces delays and manual handling.

✅ Enhanced Safety – No need for operators to manually intervene.

✅ Scalability – Easily integrate with robotic arms, vision systems, and more.

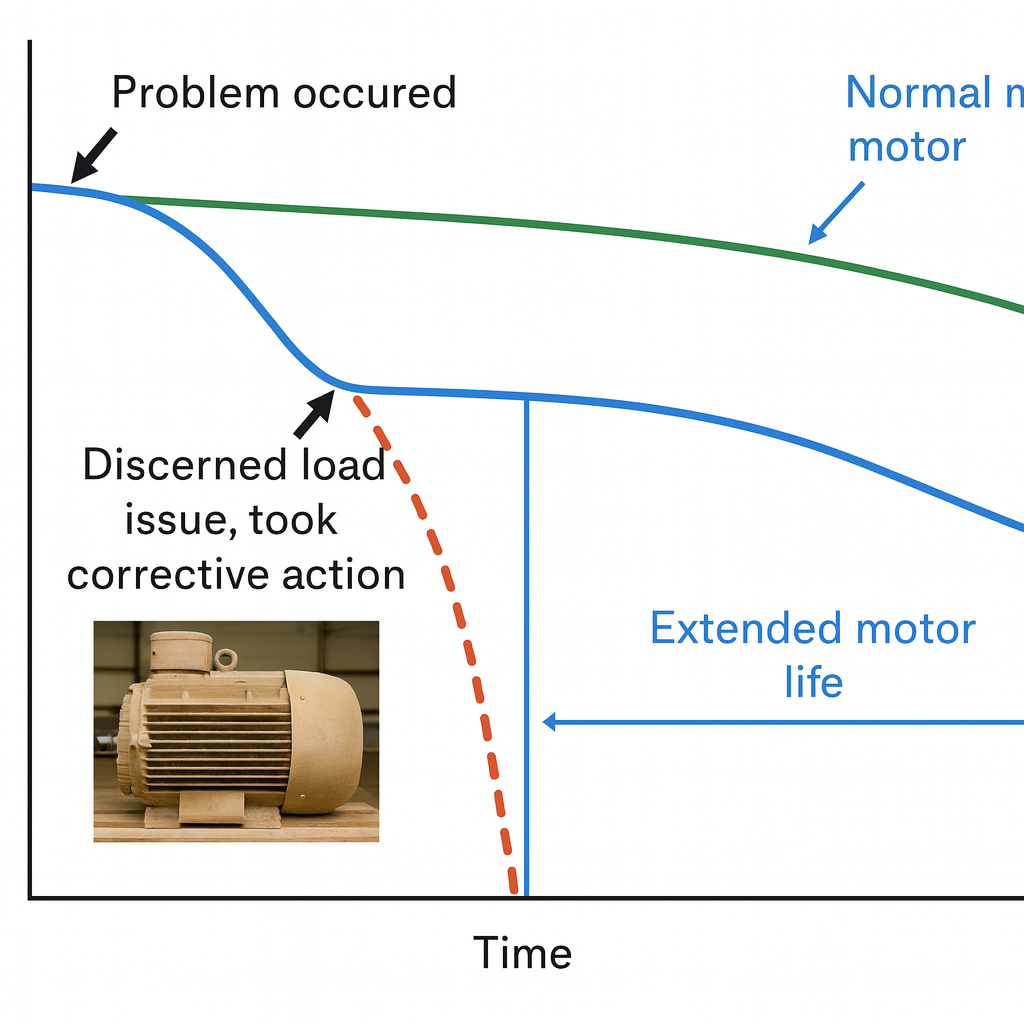

✅ Reliability – Industrial-grade components ensure long-term performance.

Why TGEP?

At TGEP, we don’t just install equipment—we deliver complete automation solutions. Our team of licensed electricians and automation experts ensures every system is:

- Code-compliant

- Efficiently wired

- Optimally programmed

- Fully tested and documented

Whether you’re upgrading an existing conveyor or building a new line from scratch, TGEP has the expertise to make it happen.