When investing in FANUC robotic automation for your packaging or warehousing operation, one of the most common questions is: How long will the installation take? The answer depends on several key factors, but in general, a single FANUC robot installation typically takes 2 to 5 days from start to finish.

Key Factors That Influence Installation Time

1. Complexity of the Automation System

The more complex your automation setup, the longer the installation may take. For example, if your FANUC robot is integrated with robotic tool changers, automated conveyors, or vision systems, additional time is required for mechanical integration, calibration, and testing. These components must be precisely aligned with the robot’s motion and control logic to ensure seamless operation.

2. Integration with PLC or SCADA Systems

A major part of any FANUC robot deployment is the integration with PLC (Programmable Logic Controller) or SCADA (Supervisory Control and Data Acquisition) systems. This step involves configuring I/O wiring, setting up communication protocols, and ensuring that the robot can interact with other equipment in your facility. The more advanced the integration, the more time is needed for programming, debugging, and validation.

3. Site Readiness

Before installation begins, your site must be prepared to support the FANUC robot. This includes:

- Power and grounding setup specific to FANUC requirements

- Mounting infrastructure for the robot base and end-of-arm tooling

- Safety systems, such as E-stop buttons, light curtains, and FANUC Dual Check Safety (DCS) zones

If these elements are already in place, installation can proceed quickly. If not, additional time will be needed to bring the site up to spec.

What’s Included in a FANUC Robot Installation?

To give you a clearer picture, here’s what our typical FANUC robot installation service includes:

- Electrical power and grounding setup

- I/O wiring between the FANUC robot and your PLC or SCADA system

- Teach pendant configuration for intuitive robot control

- DCS zone setup for enhanced safety

- Installation of robot safety devices (e.g., E-stops, light curtains)

- Full system testing and commissioning

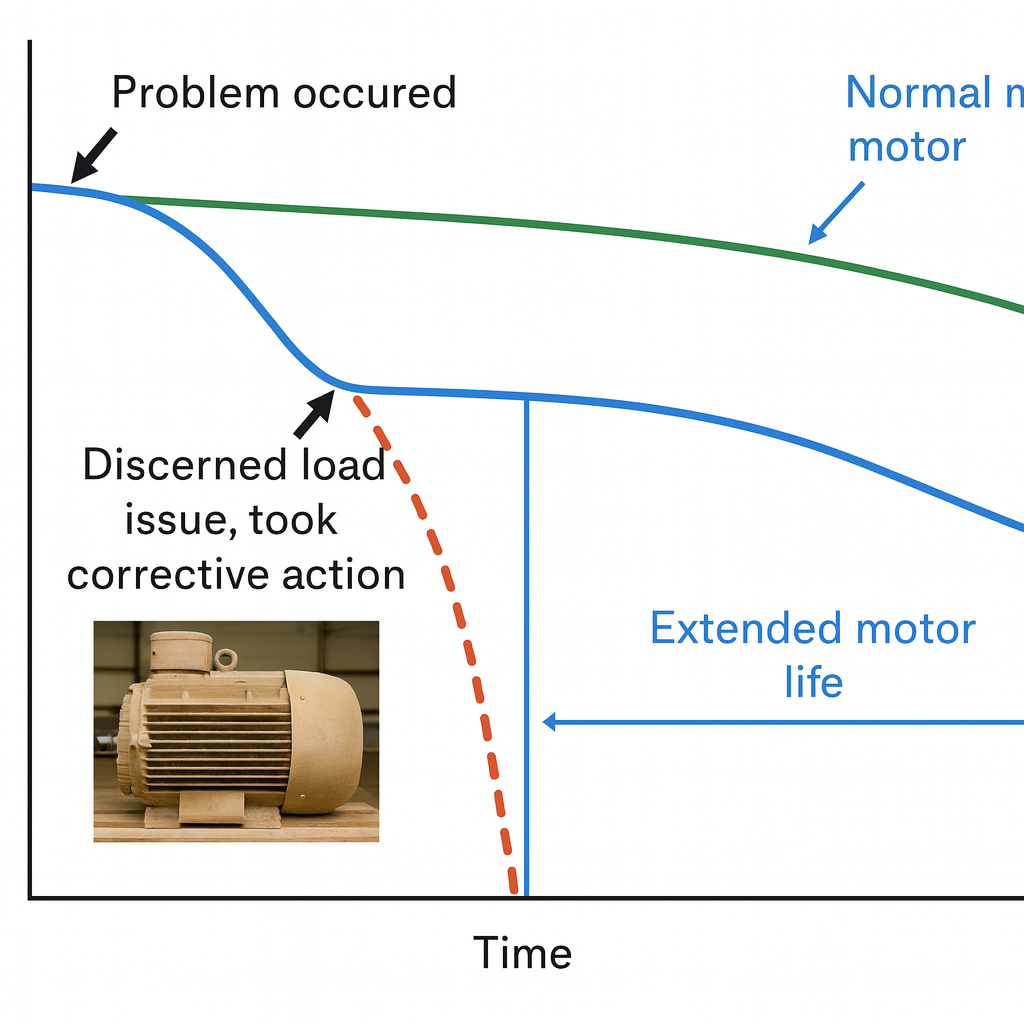

Minimizing Downtime, Maximizing ROI

Our goal is to minimize disruption to your operations while ensuring your FANUC robotic system is fully optimized for tasks like palletizing, material handling, and order fulfillment. With proper planning and site readiness, most installations are completed within a few days—getting you up and running faster and accelerating your return on investment.