In modern manufacturing and logistics, palletizing systems are essential for organizing products efficiently for storage or shipment. When combined with conveyor systems, they create a seamless flow of goods. At the heart of this automation lies the integration of Siemens PLCs and HMIs, enabling precise control, real-time monitoring, and user-friendly operation.

This blog explores how Siemens automation technology powers palletizing on conveyor systems, from hardware selection to programming and visualization.

Why Use Siemens PLC and HMI for Palletizing?

Siemens offers a unified automation ecosystem through TIA Portal, allowing seamless integration between:

- PLCs (e.g., S7-1200, S7-1500) for logic control

- HMIs (e.g., Comfort Panels) for operator interaction

- Drives and sensors for motion and feedback

This integration ensures:

- Accurate pallet placement

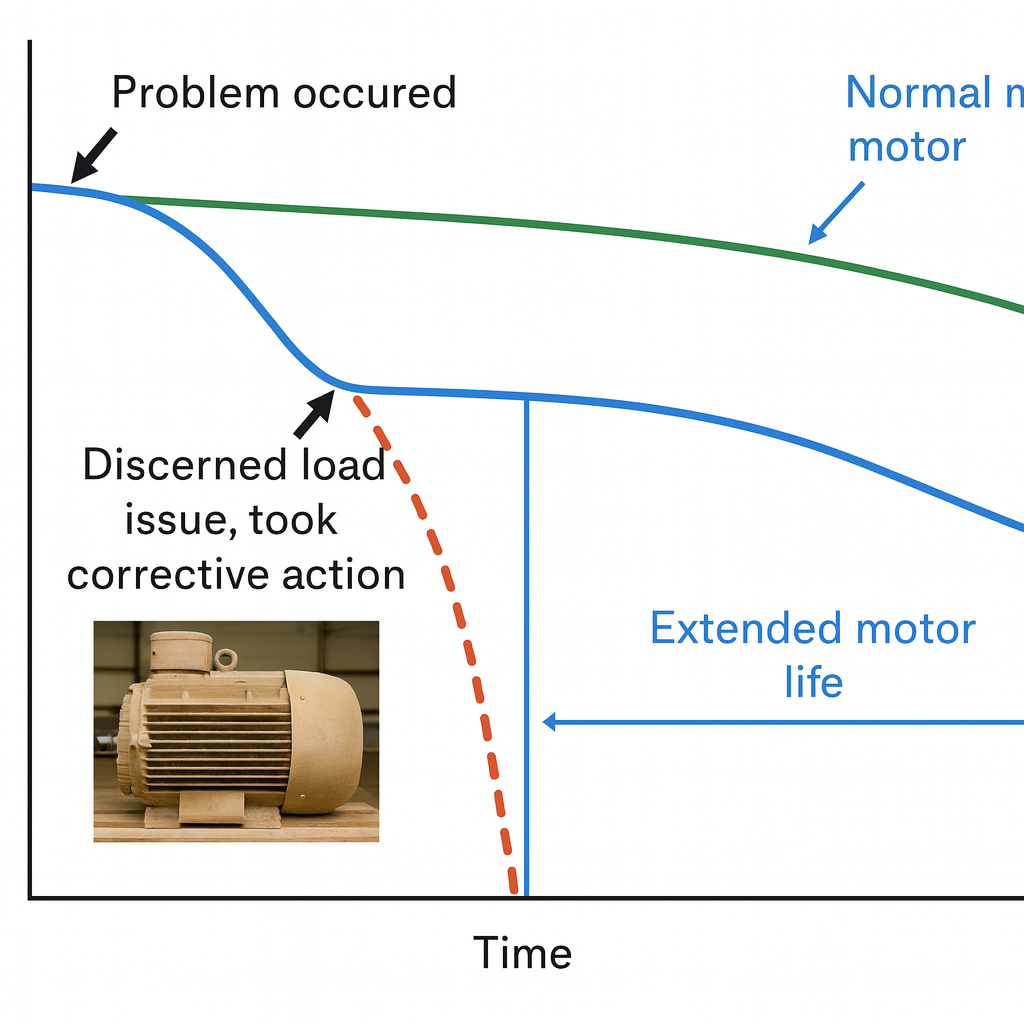

- Real-time diagnostics

- Easy troubleshooting and maintenance

- Scalable and modular system design

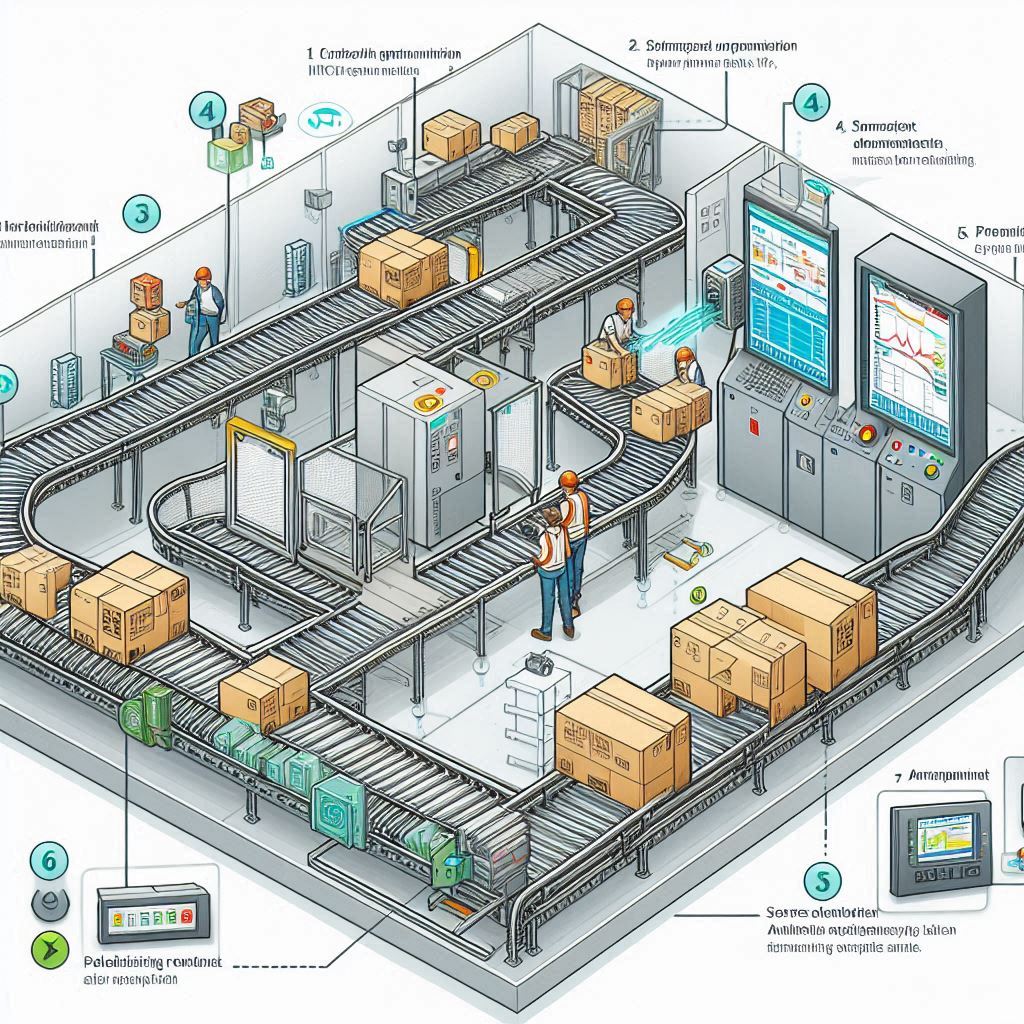

Key Components in a Palletizing Conveyor System

- Conveyor Belts – Move products to the palletizing station

- Pallet Dispensers – Feed empty pallets into position

- Pick-and-Place Robots or Gantry Systems – Stack products onto pallets

- Sensors – Detect product position, pallet presence, and alignment

- Siemens PLC – Controls the sequence and logic

- Siemens HMI – Provides a user interface for monitoring and control

Integration Workflow

1. PLC Programming in TIA Portal

- Define I/O for motors, sensors, and actuators

- Create logic for:

- Product detection

- Pallet positioning

- Stacking sequence

- Conveyor movement

- Use state machines or step sequences for structured control

2. HMI Design

- Create screens for:

- System overview

- Manual/auto mode selection

- Alarm and fault display

- Pallet count and cycle time

- Use tag synchronization to link HMI elements with PLC variables

3. Communication Setup

- Use PROFINET or Ethernet for fast, reliable communication

- Assign IP addresses and configure device topology in TIA Portal

4. Testing and Commissioning

- Simulate the process in TIA Portal or test on-site

- Validate sensor feedback and actuator response

- Fine-tune timing and safety interlocks

Example Use Case

A packaging facility uses a Siemens S7-1500 PLC to control a conveyor system that feeds boxes to a palletizing robot. A Comfort Panel HMI allows operators to:

- Start/stop the system

- View real-time palletizing status

- Acknowledge alarms

- Adjust stacking patterns

The system uses photoelectric sensors to detect box arrival and encoders to track conveyor position. The PLC coordinates the robot’s movements and ensures each layer is stacked correctly.

Best Practices

- Modular programming: Use function blocks for conveyor, palletizer, and safety logic

- Use symbolic tags: Easier to manage and link between PLC and HMI

- Implement safety: Use safety PLCs or safety relays for emergency stops and guarding

- Data logging: Track pallet counts, downtime, and errors for performance analysis

Conclusion

Integrating Siemens PLCs and HMIs in palletizing conveyor systems brings precision, flexibility, and ease of use to industrial automation. With TIA Portal, engineers can design, program, and monitor the entire system from a single platform—making Siemens a top choice for smart manufacturing.