At TGEP, we specialize in designing and installing smart control systems using Allen-Bradley, Siemens, and other leading PLC platforms. One of the most fundamental concepts in PLC programming is the use of discrete inputs—especially when compared to analog inputs. In this blog, we’ll break down what discrete inputs are, how they’re used in block programming, and why discrete switches remain essential in modern industrial automation.

🔌 What Are Discrete Inputs?

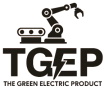

Discrete inputs (also called digital inputs) are binary signals that can only be ON (1) or OFF (0). These are typically connected to devices like:

- Push buttons

- Limit switches

- Proximity sensors

- Selector switches

- Safety interlocks

In Allen-Bradley PLCs (like the MicroLogix, CompactLogix, or ControlLogix series), discrete inputs are mapped to specific input addresses (e.g., I:1/0), and are used to trigger logic in ladder diagrams or function block programs.

🌡️ Discrete vs. Analog Inputs

| Feature | Discrete Input | Analog Input |

|---|---|---|

| Signal Type | ON/OFF (binary) | Continuous (voltage or current range) |

| Devices | Switches, sensors, buttons | Temperature sensors, pressure transducers |

| PLC Representation | Boolean (1 or 0) | Integer or floating-point value |

| Use Case | Start/stop, presence detection | Monitoring levels, speeds, temperatures |

| Complexity | Simple | Requires scaling and filtering |

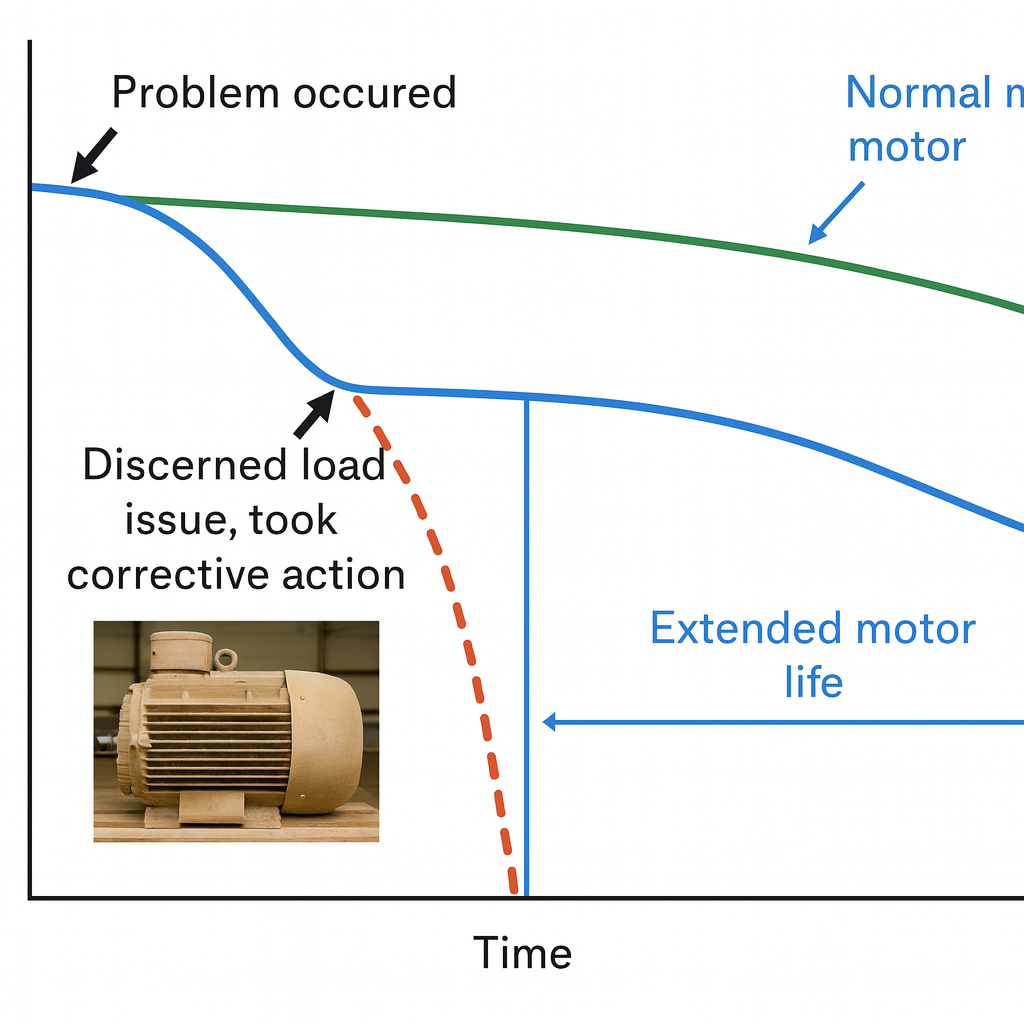

⚙️ Why Discrete Switches Still Matter

Even in advanced systems with analog sensors and smart devices, discrete switches offer:

✅ Simplicity – Easy to wire, program, and troubleshoot

✅ Reliability – Less prone to signal noise or drift

✅ Safety – Ideal for emergency stops and interlocks

✅ Cost-Effectiveness – Lower cost than analog sensors

🏭 Real-World Use at TGEP

At TGEP, we use discrete inputs in:

- Conveyor systems (e.g., proximity switches to detect packages)

- Motor control panels (e.g., selector switches for manual/auto modes)

- FANUC robot cells (e.g., safety gates and light curtains)

- EV charging stations (e.g., contactor feedback and status indicators)

🔗 Final Thoughts

While analog inputs are essential for monitoring variable conditions, discrete inputs and switches remain the backbone of industrial control systems. They provide fast, reliable, and safe control logic—especially when paired with robust PLC platforms like Allen-Bradley.

Need help designing a PLC system with discrete and analog inputs?

Contact TGEP today or visit www.tgep.net to learn how our licensed electricians and automation experts can help you build smarter, safer systems.