⚙️

In the heart of America’s manufacturing belt—from Michigan to Illinois, Indiana to Ohio—FANUC robots are the trusted workhorse in industries ranging from automotive to food processing. At TGEP Electrical Services, we specialize in FANUC robot installation, robotic safety upgrades, and PLC-to-robot integration for Midwest facilities.

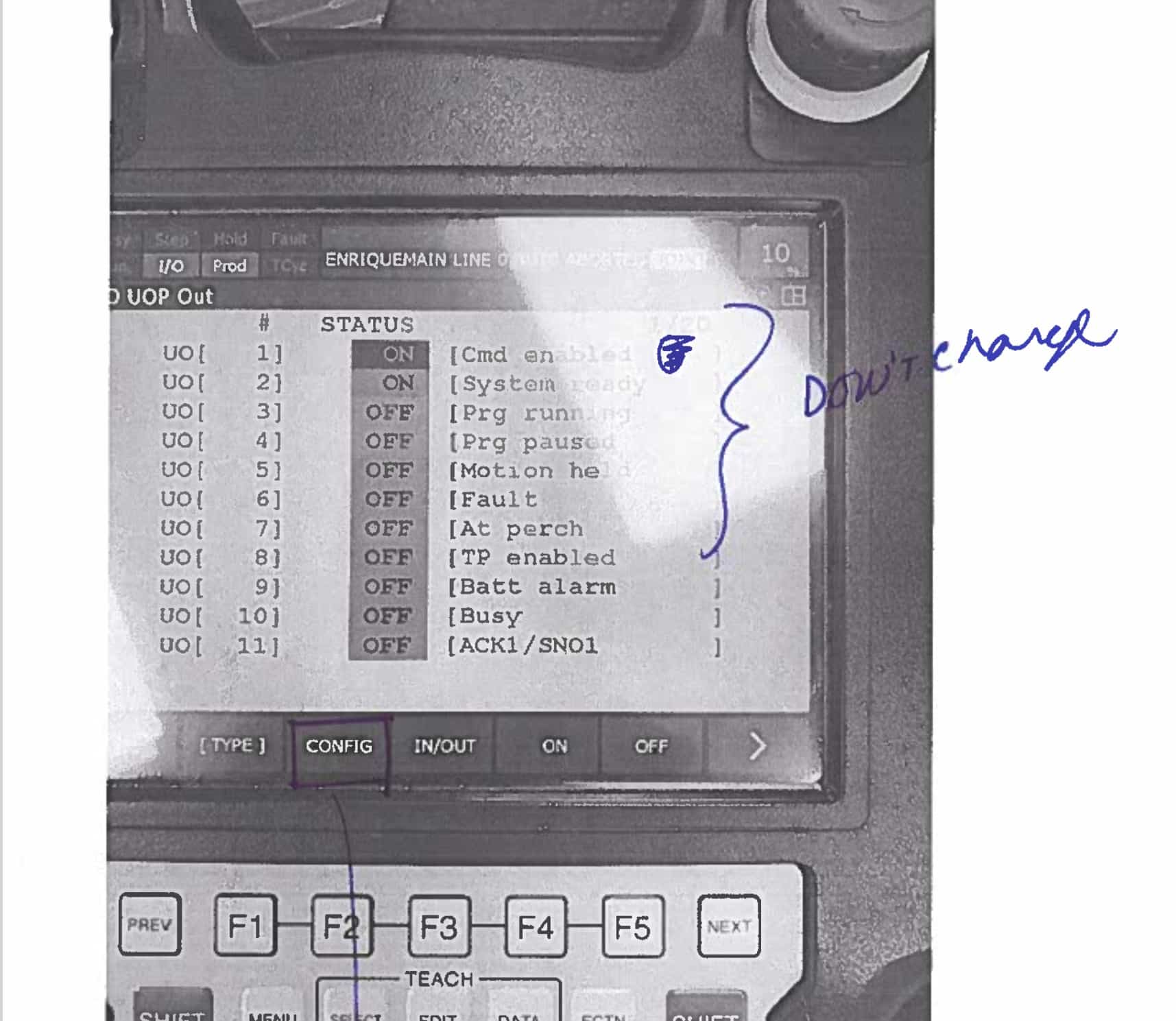

Whether you’re working in a Tier 1 automotive supplier or a small CNC shop, understanding the User Operator Panel (UOP) interface is essential for safe and efficient robot integration.

One common mistake seen in Midwest facilities is changing UOP rack values from 0 to 8 without fully understanding the implications. This blog explains why that’s risky—and how TGEP can help you avoid costly downtime.

What Is UOP in FANUC Robotics?

The User Operator Panel (UOP) is a digital interface that allows external systems—like PLCs (Programmable Logic Controllers)—to control robot functions such as:

-

Cycle Start

-

Fault Reset

-

Hold

-

Abort

-

Servo Power On/Off

These signals are configured through the FANUC iPendant (Tech Pendant) and mapped to specific I/O racks and slots.

Understanding Rack Values: 0 vs. 8

-

Rack 0: Internal simulation signals used for testing or virtual setups.

-

Rack 8: Physical I/O signals connected to real-world hardware (e.g., relays, sensors, PLCs).

Changing a UOP signal from Rack 0 to Rack 8 tells the robot to expect that signal from physical hardware—a move that can cause serious issues if not properly configured.

Why You Shouldn’t Change UOP Rack Values Without Planning

-

Loss of Signal Communication

If the physical I/O isn’t wired or configured correctly, the robot may fail to receive critical commands, causing it to freeze or fault. -

Safety Hazards

Incorrect UOP settings can bypass safety interlocks, putting operators and equipment at risk—especially in high-speed Midwest automotive lines. TGEP provides robot safety integration and DCS zone setup to mitigate these risks. -

Troubleshooting Complexity

Misconfigured UOP signals can lead to hours of downtime, especially if the change wasn’t documented or communicated to your controls team. -

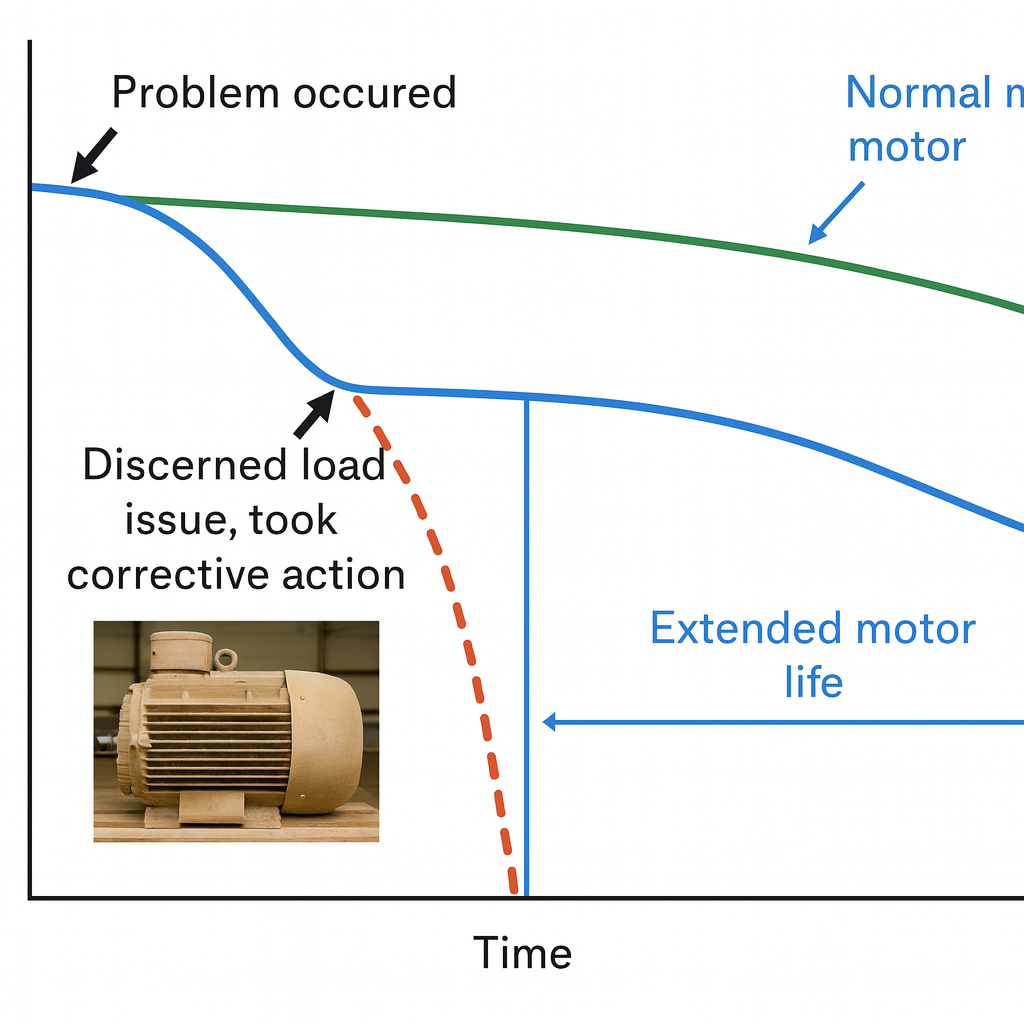

Costly Downtime

In fast-paced Midwest manufacturing environments, every minute of downtime can cost thousands in lost productivity. TGEP’s emergency FANUC support ensures rapid diagnosis and recovery.

Best Practices for Midwest Automation Teams

-

Coordinate with your PLC and controls engineers before making changes.

-

Use Rack 0 for simulation only—never for production.

-

Always document changes in your robot’s configuration log.

-

Perform a full backup before modifying UOP settings.

-

Consult with FANUC-certified integrators or local automation experts—like TGEP Electrical Services.

When Is It Safe to Use Rack 8?

Only use Rack 8 when:

-

Your physical I/O is fully wired and tested.

-

You’re integrating with a PLC or safety system.

-

You’ve verified signal logic and timing.

-

You’ve backed up your robot configuration.