The Art of Combining Smart Lighting, Siri HomeKit Automation, and Matter Technology for a Truly Intelligent Home in Illinois

“Discover how TGEP Electrical Services combines Siri HomeKit, Matter‑enabled lighting, smart thermostats, and Chamberlain garage automation to create seamless, luxury smart home experiences across Illinois. Learn how professional installation transforms everyday living into intelligent automation.”

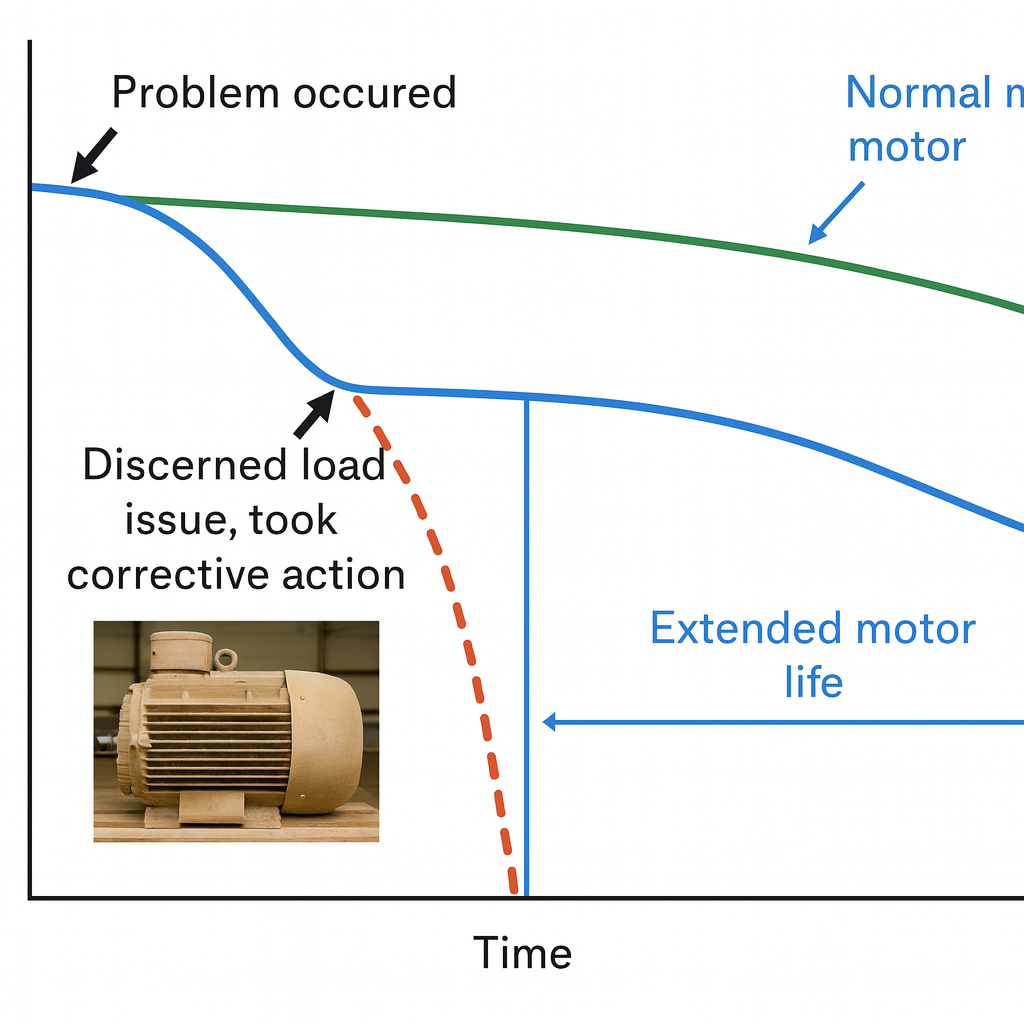

Preventive Maintenance on Motors: TGEP’s Approach

Preventive motor maintenance is the key to reliability and safety. At TGEP Electrical Services, we use predictive testing and system-level inspections to detect issues early, extend motor life, and avoid costly downtime. Our proactive approach ensures motors powering HVAC, automation, and electrical systems run efficiently for homeowners and businesses across Will and DuPage Counties.

Combing Electric Motor Drives for smoother Process

Electric Motor Drives has become a more common feature in Electric Motor installation. One of the common Electric Motor Drives commonly used around the Joliet, Plainfield, Minooka area Allen Bradley Power Flex 40. Lots of industries around here add power d drives with the Electric AC motor for conveyor Belt system. At TGEP we feel having multiple Electric Drives for a long conveyor system is a easy way ti reduce load on a single drive and motor and increase the longevity of the equipment. At TGEP we also recommend connecting the motor drives together on a network or through analog input is the best way to have dependent drives which perform based on how the other motor drives are operating. In the analog input for connecting the Electric Motor Drives we make one drive the master and the other one the slave. Maybe in today world the more appropriate term would be a leader and follower. The slave drive follows the master driver and you can set it up to mirror each other. The Power Flex Motor Drives is connected through a shield cable. Benefits of Connecting Multiple PowerFlex Drives Connecting multiple PowerFlex drives offers several advantages: Centralized Control: The master power flex can control the slave and make the automation streamlined and reducing programming for slaves. Scalability: Easily add more drives by adding more drives without redesigning the entire control architecture. Reduced Wiring: Shared inputs and daisy-chained signals minimize wiring effort and panel space. Synchronized Operation: Ideal for applications like conveyors, mixers, or multi-motor systems where coordinated speed and direction are essential. Cost Efficiency: Fewer components and simplified installation reduce labor and hardware costs. Improved Diagnostics: If you’re planning a multi-drive setup, TGEP can help with installing the wiring layout, A/C Electric Motor and Allen Bradley Power Flex around Will County, Dupage County. TGEP does Electric Services around A/C or DC motor in Joliet, Plainfield, Naperville area. Want to explore how to integrate these drives with a PLC or HMI next call us 630-847-1421

Making Home Automation Simple and Affordable

The term “Home Automation” often sounds complex and expensive to many consumers. But in reality, it doesn’t have to be. Automating your home doesn’t mean wiring up every room with high-tech gadgets—it can be as simple as streamlining one or two everyday tasks. For example, I have elderly parents, and I often worry about whether they’ve turned off the lights before bed or remembered to shut off the stove. If you’re an iPhone user and want a simple way to check on your loved ones, home automation can help—without breaking the bank. A Simple Solution with Lutron One easy and affordable way to get started is by using a Lutron Caséta hub and smart switch. This setup allows you to automate a single light switch—like the one in a bedroom—so you can monitor and control it remotely. Cost: Around $110 for the hub and switch combo. App: Download the Lutron App from the App Store to your iPhone. Make Sure Its from Lutron not other company. Installation: If you’re not comfortable with electrical work, call a licensed electrician. If you’re in the Midwest region of Illinois, TGEP is a reliable company that can handle the installation. Setup Steps Connect the Hub: Plug the Lutron hub into your modem’s Ethernet port (or a connected switch). Configure the Hub: Press the black button on the hub when prompted to sync it with your home network. Install the Switch: Once wired, open the Lutron app and tap “Add Device.” Pair the Switch: Press the bottom of the switch until the light flashes. The app will automatically detect and add it to your system. And just like that—voilà!—you’ve created a simple home automation setup that gives you peace of mind and helps your loved ones stay safe.

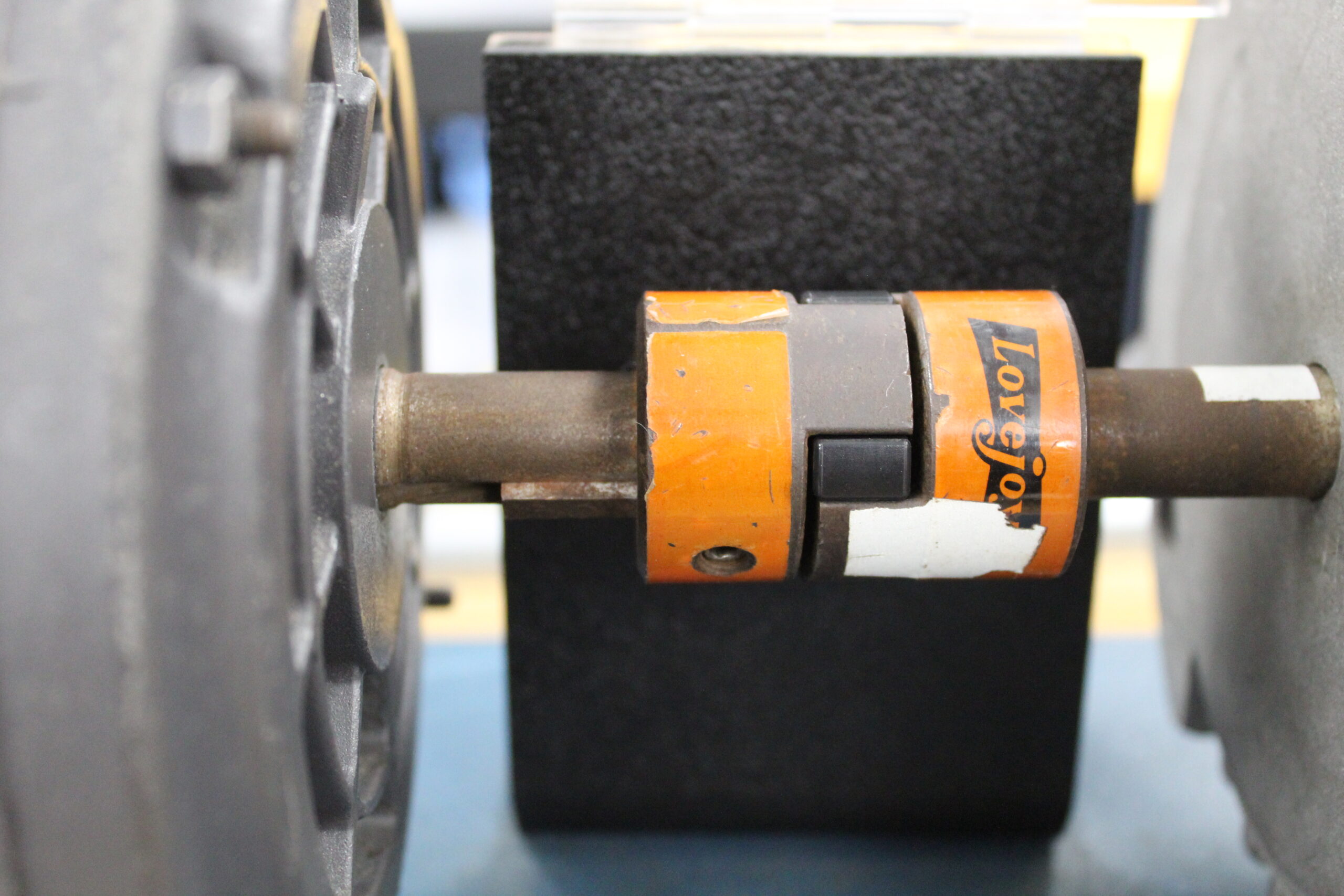

The Art of Motor Coupling: Connecting Power to Performance

In the world of industrial automation and mechanical systems, electric motors are the heartbeat of productivity. From powering conveyor belts in manufacturing plants to driving pumps in water treatment facilities, electric motors are everywhere. But their power is only as effective as the connection to the equipment they drive — and that’s where motor couplings come into play. Why Motor Couplings Matter AC or DC Motor couplings are essential components that connect electric motors to driven equipment such as pumps, fans, and conveyors. They serve a critical role in transmitting torque while accommodating misalignment, reducing vibration, and protecting both the motor and the driven machinery from excessive wear. In Will County lots of industries deploy AC or DC motors for various uses. A well-selected and properly aligned coupling can: Extend motor life Improve system efficiency Minimize downtime Reduce maintenance costs Types of Motor Couplings at TGEP LLC we Install and Service At our company, we specialize in the installation and servicing of all major types of motor couplings, including: 🔹 Sure-Flex Couplings Flexible and easy to install, Sure-Flex couplings are ideal for applications where misalignment and shock loads are common. Their elastomeric design helps dampen vibration and noise. 🔹 Gear Couplings Known for their high torque capacity and durability, gear couplings are perfect for heavy-duty applications. They consist of two hubs with external gear teeth and a sleeve with internal teeth. 🔹 Chain Couplings These couplings use a roller chain and sprockets to transmit torque. They are rugged and reliable, often used in conveyor systems and other industrial machinery. 🔹 Grid Couplings Grid couplings offer excellent vibration damping and shock absorption. Their unique grid spring design makes them suitable for high-speed and high-torque applications. The Importance of Proper Coupling Selection and Alignment Choosing the right coupling isn’t just about matching torque ratings — it’s about understanding the application. Factors like misalignment tolerance, operating speed, environmental conditions, and load characteristics all influence the best choice. Equally important is precision alignment. Misaligned couplings can lead to: Increased vibration Premature bearing and seal failure Excessive energy consumption Using laser alignment tools and expert techniques, we ensure every coupling is installed to exact specifications, maximizing performance and longevity. Couplings in Conveyor Systems In conveyor systems, motor couplings play a pivotal role in ensuring smooth and efficient material handling. Whether it’s a belt conveyor in a packaging line or a screw conveyor in a grain processing plant, the right coupling ensures consistent motion and minimal mechanical stress. Final Thoughts The art of motor coupling lies in the balance between power transmission and mechanical harmony. We at TGEP try find the right coupling for the application, With the right coupling, properly installed and aligned, electric motors can deliver peak performance while minimizing wear and tear on connected equipment. Whether you’re upgrading your system or troubleshooting vibration issues, our team is here to help with expert advice and hands-on service for all major coupling types.

Electric Vehicle Charging Station Glendale Heights, IL

How to Set Up an As electric vehicles (EVs) become more popular, the need for reliable and accessible charging stations is growing. If you’re planning to install an EV charging station in Glendale Heights, Illinois, it’s important to follow local regulations and safety standards. This guide outlines the key steps: 1. Permitting Process Before installation, you must obtain the proper permits from the Community Development Department. Where to Apply: In Person: 300 Civic Center Drive, Glendale Heights, IL 60139 By Mail, Fax, or Email: Fax: 630.260.1317 Email: permits@glendaleheights.org Who Can Apply: Property owners or authorized contractors registered with the Village. Required Documents: Site plan Electrical drawings Load calculation sheet HOA approval letter (if applicable) Engineer/architect seal (if project cost exceeds $10,000) 2. Electrical Load Calculations Load calculations ensure your electrical system can support the EV charger. Charger Types: Level 1 (120V): Minimal load; no permit needed if using existing outlets. Level 2 (240V): Requires a permit and load calculations. Load Calculation Sheet Must Include: Size of existing service panel Existing electrical load Proposed load from EV charger Circuit breaker size Conductor types and sizes Conduit specifications 3. Electrical Drawings These are required for permit approval and safe installation. Include the Following: Single-line diagram (power source, circuit breaker, conduit/wiring path, charger location) Site plan (parking layout, charger mounting height, ADA compliance if public access) Manufacturer specifications for the EVSE (Electric Vehicle Supply Equipment) 4. Electrician Registration & Bonding Electricians must be registered with the Village to perform work. Who Must Register: Any electrician or electrical contractor working in Glendale Heights. Required Documents: Completed Contractor Registration Application $20,000 Surety Bond (Plumbing contractors exempt) Valid electrical license from an approved municipal corporation Fees: Registration Fee: $75 Fee Waiver: Available for electricians with a valid municipal license Submit Registration: In Person: Community Development Department By Email: permits@glendaleheights.org By Fax: 630.260.1317 Final Tips Start Early: Permit approval may take up to 14 days, especially if revisions are needed. Hire Licensed Professionals: Ensure your contractor is registered with the Village. Plan for Expansion: Consider installing EVSE-ready infrastructure for future scalability.

LED Light Blinking with Lutron Caseta Smart Switch in Office Automation Projects – Naperville, IL

LED lights blinking after installing a Lutron Caseta Smart Switch in a three-way setup? Discover how the LUT-MLC capacitor resolves this common issue in smart home and office automation projects across Naperville, IL. Ideal for homeowners and businesses upgrading to intelligent lighting systems.

Boosting Production Efficiency with PLC-Driven Palletizing Conveyors: TGEP’s Midwest Expansion

TGEP enhances production efficiency in Naperville and the Midwest with the installation of motorized palletizing conveyors integrated with PLC systems—delivering smarter automation and streamlined operations for local industries.

Brightening the Future: Office Automation for a Modern Medical Office Condo by TGEP

TGEP, a Midwest electrical company, modernized a medical office condo by replacing outdated fluorescent lighting with LED fixtures and integrating Lutron smart switches. The upgrade eliminated flickering, humming, and inefficiencies—creating a quieter, smarter, and more energy-efficient workspace.

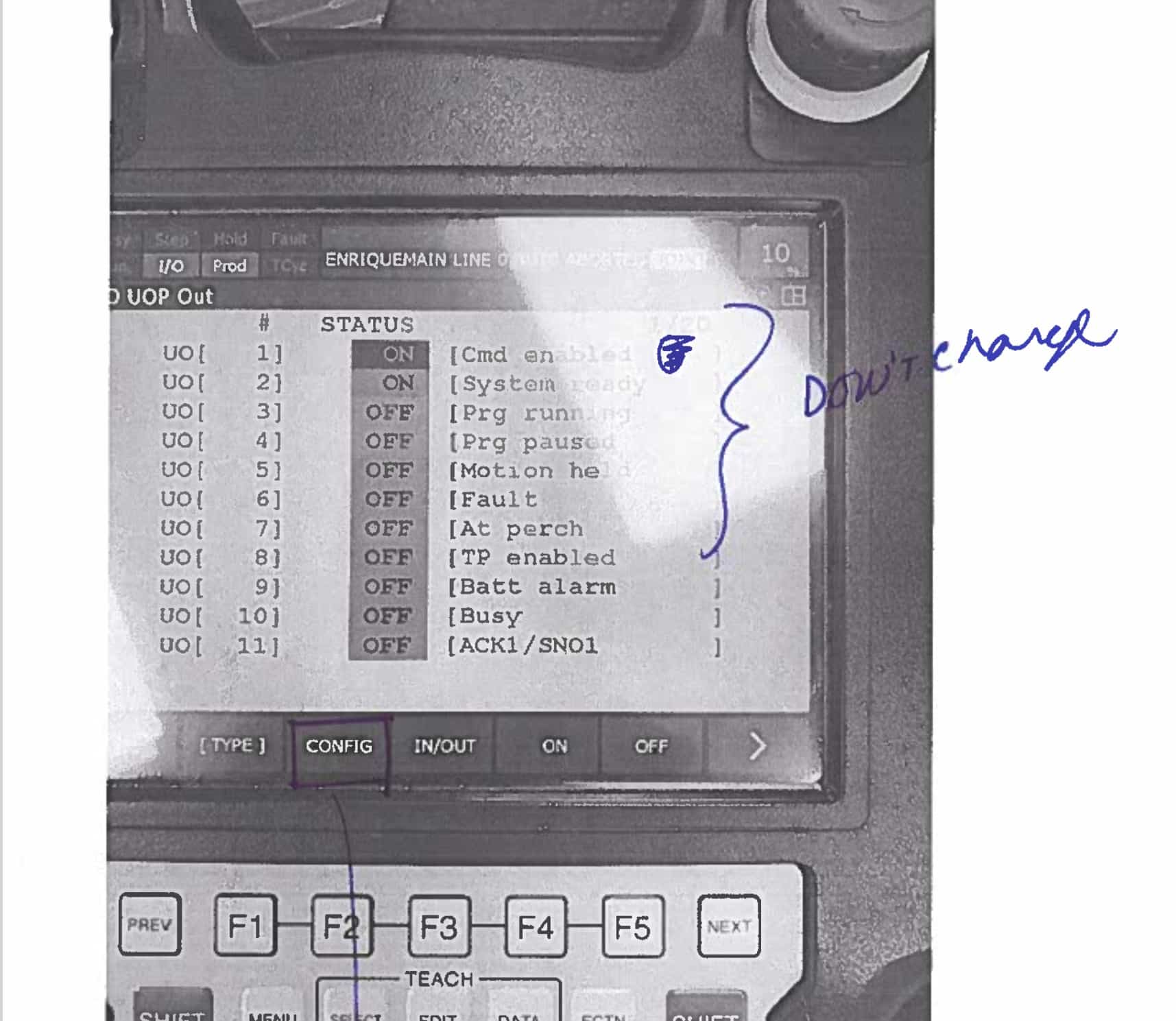

Understanding UOP in FANUC Robots: Why You Shouldn’t Change Some Values.

Changing UOP rack values on your FANUC robot without proper setup can lead to faults, safety risks, and lost production. TGEP Electrical Services explains the risks and best practices for safe integration with PLC systems across Midwest industries.