In the fast-paced world of industrial automation, every second of downtime costs money. Many companies rely on in-house maintenance teams to keep operations running smoothly. While these teams are invaluable for routine maintenance and minor troubleshooting, there are times when calling in a specialized vendor is not just a good idea—it’s essential.

At TGEP, we’ve seen firsthand how well-intentioned maintenance efforts can go sideways when it comes to complex systems like FANUC robots or PLCs. Here’s why—and when—you should consider bringing in the pros.

1. When the Problem Is Beyond Routine Maintenance

FANUC robots and PLCs are powerful, but they’re also intricate. If your issue involves:

- Reprogramming or modifying robot paths

- Integrating new equipment or sensors

- Troubleshooting communication errors between devices

- Updating firmware or software

…it’s time to call a vendor. These tasks require deep technical knowledge and experience that most general maintenance teams simply don’t have.

2. When Downtime Is Not an Option

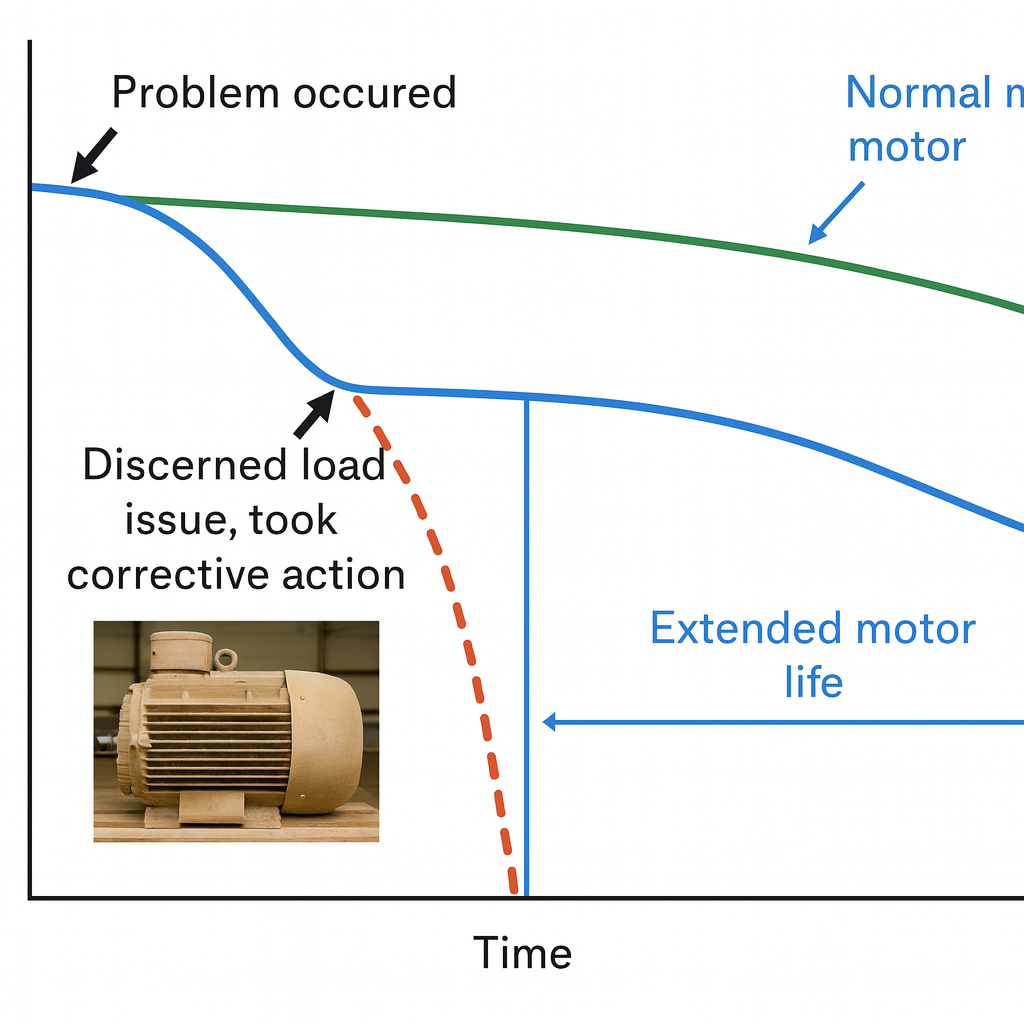

Production schedules are tight, and every minute counts. A misstep in troubleshooting a robot or PLC can lead to:

- Extended downtime

- Lost production

- Damaged equipment

- Safety hazards

Hiring a vendor ensures the problem is diagnosed and resolved quickly and correctly the first time, minimizing costly delays.

3. When You’re Scaling or Upgrading

Installing a new FANUC robot or upgrading your PLC system isn’t just plug-and-play. It involves:

- System design and layout

- Electrical and network integration

- Safety compliance

- Testing and commissioning

Vendors bring the tools, training, and experience to handle these projects efficiently and safely.

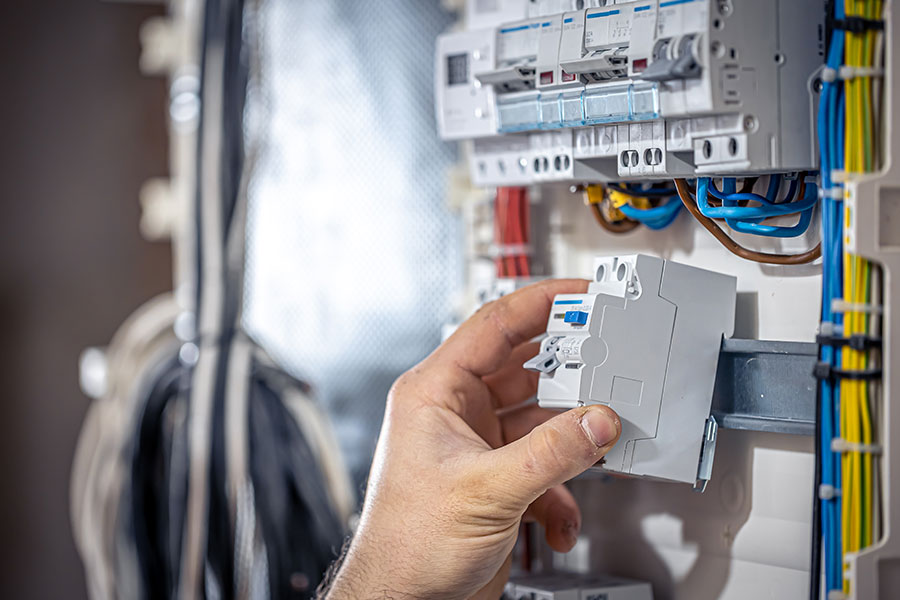

4. When Compliance and Safety Are on the Line

Industrial automation systems must meet strict safety and compliance standards. A misconfigured robot or PLC can create serious risks. Certified vendors understand:

- OSHA and NFPA 70E standards

- Lockout/tagout procedures

- Risk assessments and safety interlocks

They ensure your systems are not only functional but also compliant and safe.

5. When You’ve Already Tried… and It’s Getting Worse

We’ve all seen it: a maintenance tech tries to fix a robot issue, only to accidentally overwrite a program or misconfigure a PLC. Suddenly, a minor issue becomes a major outage.

If your team is unsure, it’s better to pause and call in a vendor than to risk making things worse.

The Bottom Line

Your maintenance team is your first line of defense—but they don’t have to go it alone. Partnering with TGEP for FANUC robot or PLC work can:

- Prevent costly mistakes

- Reduce downtime

- Improve system performance

- Ensure safety and compliance

At TGEP, we specialize in helping manufacturers get the most out of their automation systems. Whether it’s a new installation, a tricky troubleshooting job, or a full system upgrade, we’re here to help—so your team can focus on what they do best.