Preventive Maintenance on Motors: TGEP’s Approach

🔧 Why Motor Preventive Maintenance Matters

- Motors are the cornerstone of operations: They power conveyors, pumps, fans, and production-line machinery. A single failure can halt business-critical processes and disrupt revenue generation.

- Downtime is expensive: Unplanned stoppages not only delay production but also increase repair costs and shorten equipment lifespan.

- Reliability drives profitability: Safe, continuous operation of motor systems directly supports business objectives and client satisfaction.

🛠️ TGEP’s Preventive Maintenance Practices

At TGEP Electrical Services, we treat motors as part of a complete system—including the motor itself, its power source, and the equipment it drives. Our preventive maintenance program includes:

- Static (off-line) testing

- Conducted periodically when motors are offline.

- Detects insulation breakdown, winding resistance issues, and potential electrical faults before they escalate.

- Dynamic (in-service) testing

- Performed while motors are running under normal load.

- Identifies real-time issues such as vibration, misalignment, and power quality fluctuations.

- Condition-based monitoring

- Continuous tracking of motor health using tools like infrared thermography, vibration analysis, and motor current signature analysis.

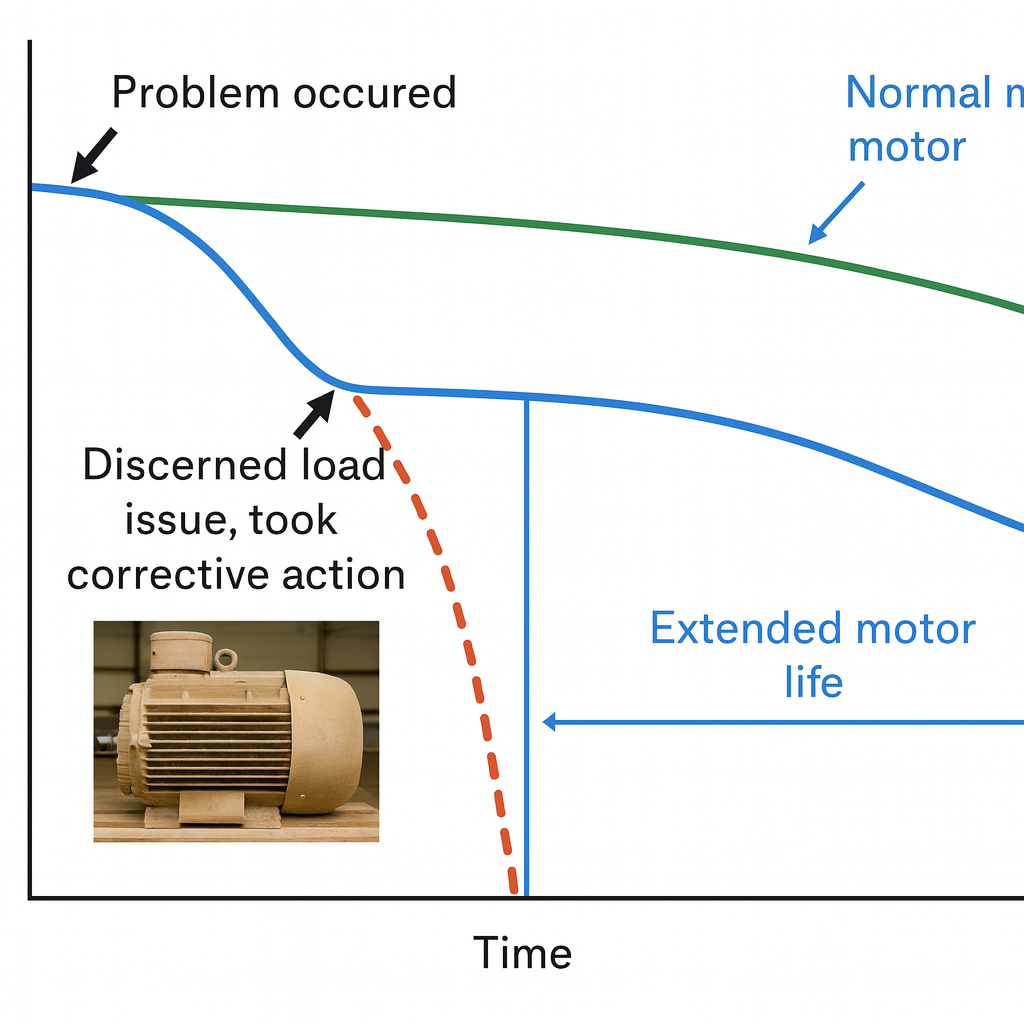

- Allows early detection of abnormalities, preventing minor issues from becoming major failures.

- System-level inspections

- Checking cables, connections, and load conditions.

- Ensuring motors are not only functional but optimized for efficiency and safety.

⚡ Benefits of Preventive Maintenance

- Extended motor lifespan: Regular testing and monitoring reduce wear and tear.

- Reduced costs: Prevents expensive emergency repairs and premature equipment replacement.

- Improved safety: Minimizes risks of electrical faults or mechanical breakdowns.

- Optimized performance: Motors run more efficiently, lowering energy consumption and operational costs.

🏠 Why It Matters for TGEP Clients

For homeowners and businesses in Will County, DuPage, Cook County, and beyond, preventive maintenance ensures that luxury automation systems, HVAC units, and critical electrical infrastructure remain reliable. Whether it’s a rooftop HVAC motor or a conveyor system in a commercial facility, TGEP’s proactive approach safeguards both comfort and productivity.

Conclusion

Preventive motor maintenance is not just about fixing problems—it’s about anticipating them before they occur. At TGEP, we integrate predictive testing, system-level inspections, and continuous monitoring to deliver maximum reliability, safety, and efficiency for every client. This proactive strategy ensures that motors remain a trusted driver of both daily operations and long-term success.