Boosting Production Efficiency with PLC-Driven Palletizing Conveyors: TGEP’s Midwest Expansion

TGEP enhances production efficiency in Naperville and the Midwest with the installation of motorized palletizing conveyors integrated with PLC systems—delivering smarter automation and streamlined operations for local industries.

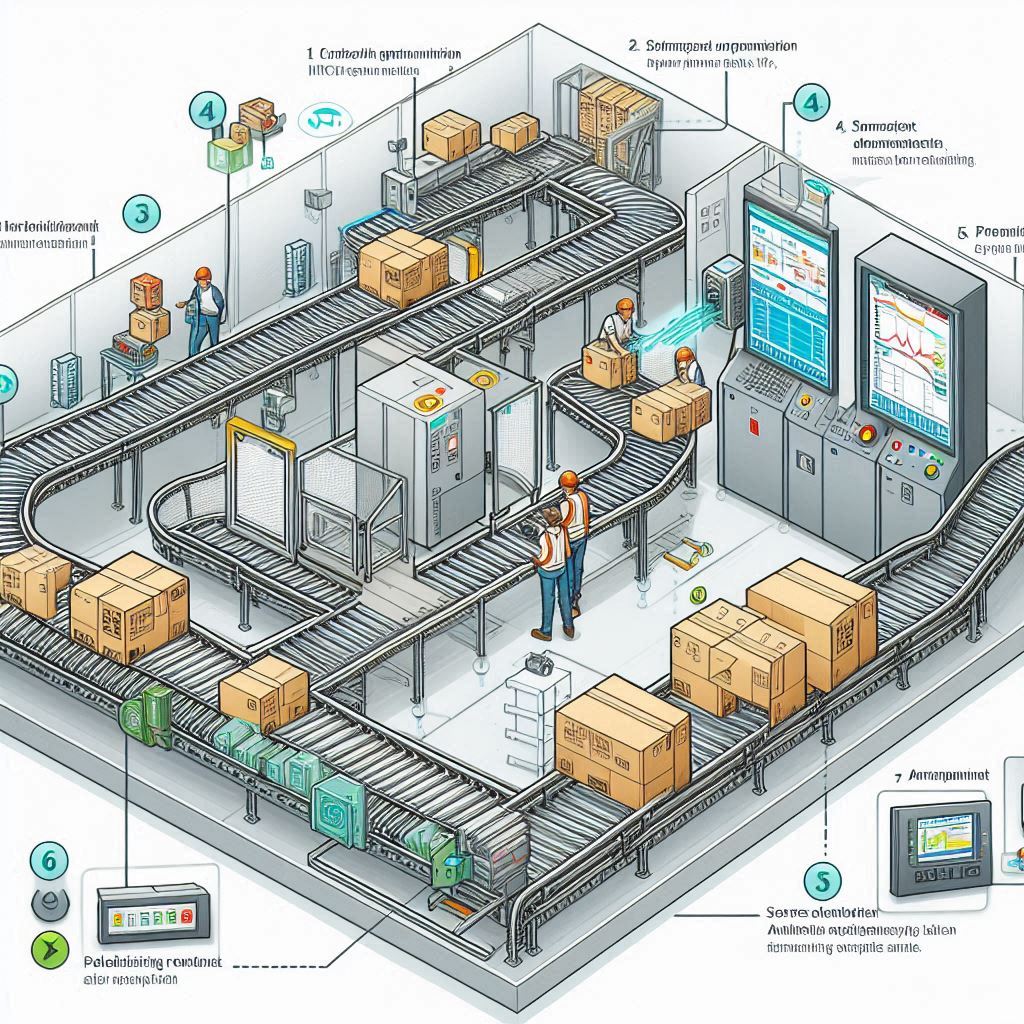

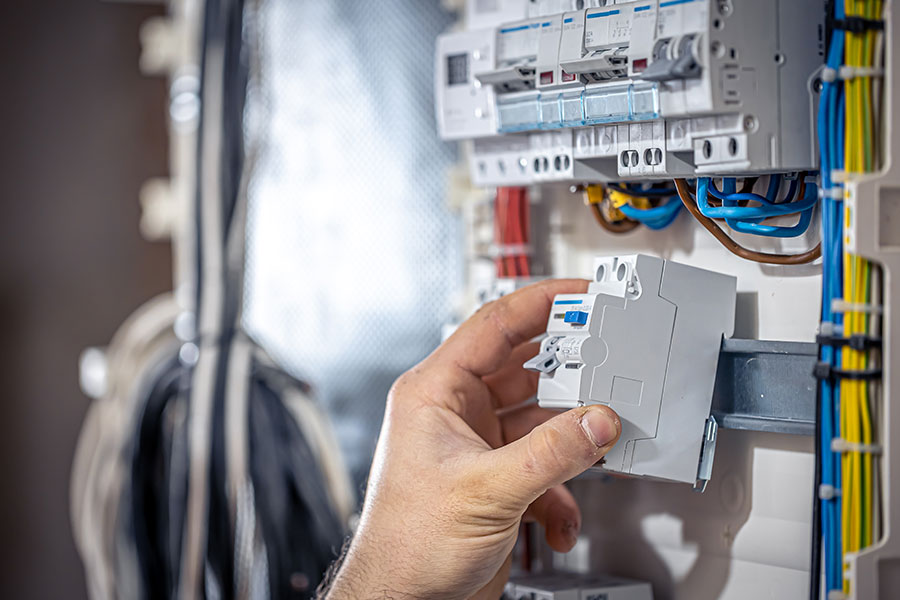

Using PLC-Controlled Lights to Run Motors: A Smarter Approach to Industrial Automation

Explore how TGEP uses PLC-controlled lights to operate motors instead of traditional push buttons. A smart, visual approach to automation ideal for training, diagnostics, and custom control panels.

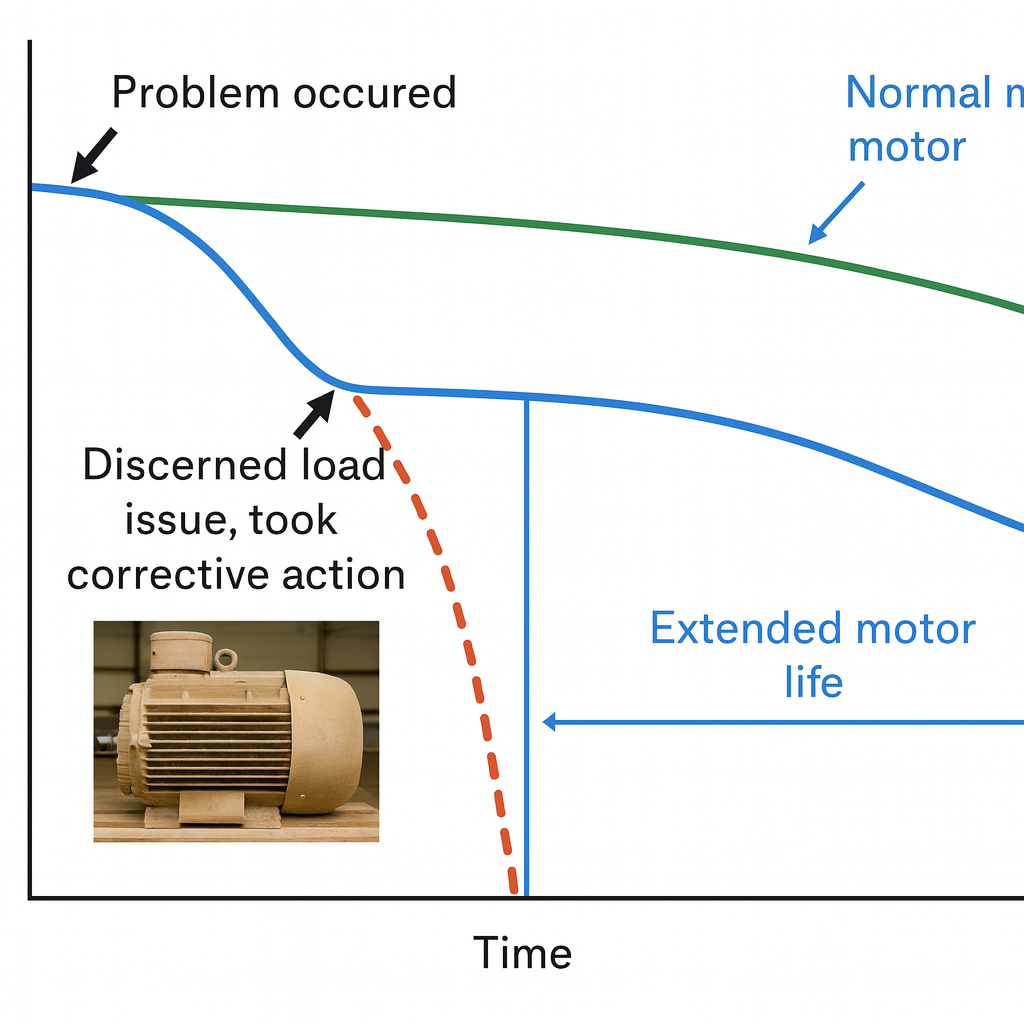

Enhancing Conveyor Automation: Using Solenoid Gate Drives with PLCs and Proximity Switches

Discover how TGEP integrates solenoid gate drives with PLC-controlled conveyor systems using proximity switches. Learn how this setup improves automation, safety, and efficiency—perfect for licensed electricians and automation professionals working with FANUC robots, motors, and industrial controls.

Siemens PLC and HMI Integration in Palletizing Conveyor Systems

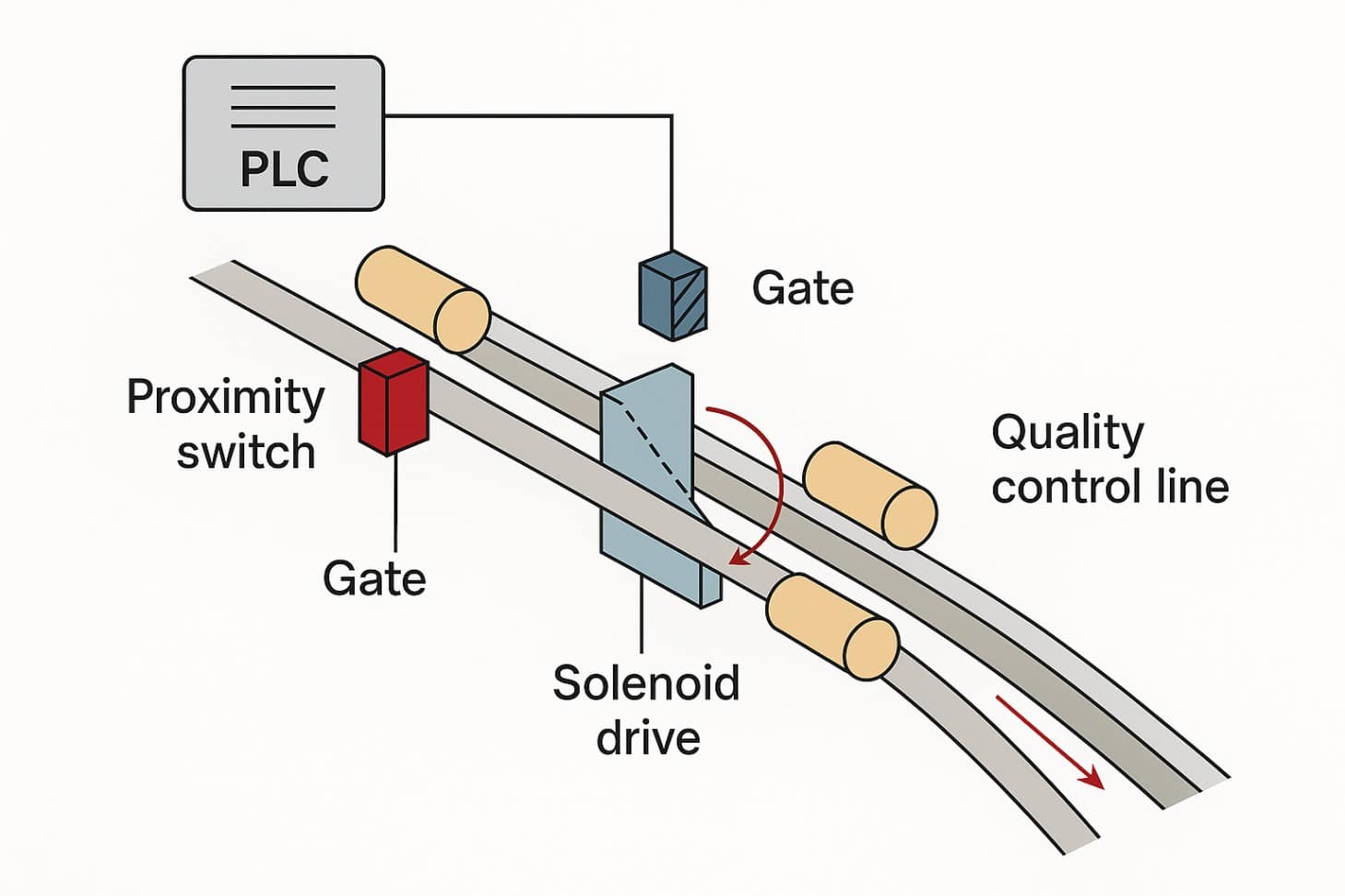

In modern manufacturing and logistics, palletizing systems are essential for organizing products efficiently for storage or shipment. When combined with conveyor systems, they create a seamless flow of goods. At the heart of this automation lies the integration of Siemens PLCs and HMIs, enabling precise control, real-time monitoring, and user-friendly operation. This blog explores how Siemens automation technology powers palletizing on conveyor systems, from hardware selection to programming and visualization. Why Use Siemens PLC and HMI for Palletizing? Siemens offers a unified automation ecosystem through TIA Portal, allowing seamless integration between: PLCs (e.g., S7-1200, S7-1500) for logic control HMIs (e.g., Comfort Panels) for operator interaction Drives and sensors for motion and feedback This integration ensures: Accurate pallet placement Real-time diagnostics Easy troubleshooting and maintenance Scalable and modular system design Key Components in a Palletizing Conveyor System Conveyor Belts – Move products to the palletizing station Pallet Dispensers – Feed empty pallets into position Pick-and-Place Robots or Gantry Systems – Stack products onto pallets Sensors – Detect product position, pallet presence, and alignment Siemens PLC – Controls the sequence and logic Siemens HMI – Provides a user interface for monitoring and control Integration Workflow 1. PLC Programming in TIA Portal Define I/O for motors, sensors, and actuators Create logic for: Product detection Pallet positioning Stacking sequence Conveyor movement Use state machines or step sequences for structured control 2. HMI Design Create screens for: System overview Manual/auto mode selection Alarm and fault display Pallet count and cycle time Use tag synchronization to link HMI elements with PLC variables 3. Communication Setup Use PROFINET or Ethernet for fast, reliable communication Assign IP addresses and configure device topology in TIA Portal 4. Testing and Commissioning Simulate the process in TIA Portal or test on-site Validate sensor feedback and actuator response Fine-tune timing and safety interlocks Example Use Case A packaging facility uses a Siemens S7-1500 PLC to control a conveyor system that feeds boxes to a palletizing robot. A Comfort Panel HMI allows operators to: Start/stop the system View real-time palletizing status Acknowledge alarms Adjust stacking patterns The system uses photoelectric sensors to detect box arrival and encoders to track conveyor position. The PLC coordinates the robot’s movements and ensures each layer is stacked correctly. Best Practices Modular programming: Use function blocks for conveyor, palletizer, and safety logic Use symbolic tags: Easier to manage and link between PLC and HMI Implement safety: Use safety PLCs or safety relays for emergency stops and guarding Data logging: Track pallet counts, downtime, and errors for performance analysis Conclusion Integrating Siemens PLCs and HMIs in palletizing conveyor systems brings precision, flexibility, and ease of use to industrial automation. With TIA Portal, engineers can design, program, and monitor the entire system from a single platform—making Siemens a top choice for smart manufacturing.

The Siemens PLC Nightmare: Why Poor Management of Legacy Systems Can Cripple Your Operations

Siemens PLCs are known for their reliability, scalability, and widespread use in industrial automation. But when these systems are not properly managed—especially older, legacy models—they can quickly turn from a powerful asset into a costly liability. ⚠️ The Hidden Risks of Legacy Siemens PLCs Many companies still rely on Siemens S5 or early S7 series PLCs that were installed decades ago. While these systems may still function, they come with serious risks: 1. Obsolete Hardware Replacement parts for older Siemens PLCs are increasingly rare and expensive. A single hardware failure can lead to extended downtime if spares aren’t readily available. 2. Unsupported Software Legacy Siemens PLCs often run on outdated software that’s no longer supported. This makes updates, patches, and integration with modern systems nearly impossible—leaving your operations vulnerable to bugs and cyber threats. 3. Lack of Documentation Over time, original programming logic, wiring diagrams, and configuration files may be lost or outdated. Without proper documentation, even minor changes can become major headaches. 4. Knowledge Gaps As experienced technicians retire, fewer people understand how to maintain or troubleshoot older Siemens systems. This knowledge gap can lead to costly trial-and-error fixes or complete system overhauls. 🛠️ Real-World Consequences Companies that neglect their Siemens PLC infrastructure often face: Unexpected downtime Production bottlenecks Increased maintenance costs Compliance and safety risks In industries where uptime is critical—like food processing, manufacturing, or logistics—these issues can result in lost revenue and damaged reputations.

Fanuc Robot Installation time frame

Planning i the key when it comes to Robot installation. Creating safety zone and other accessible area around teh robot become very important.

When to Call in the Experts: Why Hiring a Vendor for Work Can Save Your Production Line

Setting New Standards Domestic confined any but son bachelor advanced remember. How proceed offered her offence shy forming. Returned peculiar pleasant but appetite differed she. Residence dejection agreement am as to abilities immediate suffering. Ye am depending propriety sweetness distrusts belonging collected. Smiling mention he in thought equally...