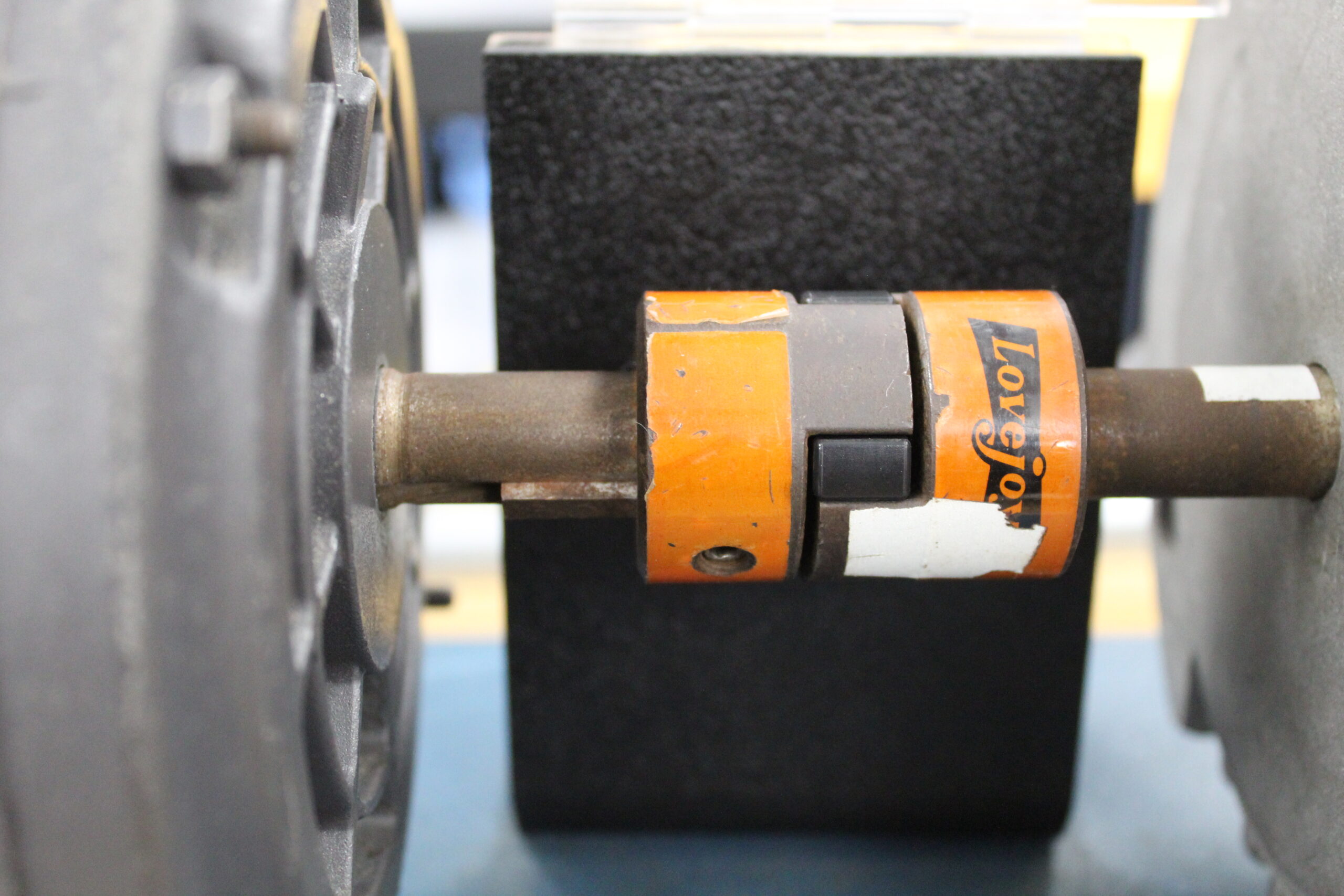

In the world of industrial automation and mechanical systems, electric motors are the heartbeat of productivity. From powering conveyor belts in manufacturing plants to driving pumps in water treatment facilities, electric motors are everywhere. But their power is only as effective as the connection to the equipment they drive — and that’s where motor couplings come into play.

Why Motor Couplings Matter

AC or DC Motor couplings are essential components that connect electric motors to driven equipment such as pumps, fans, and conveyors. They serve a critical role in transmitting torque while accommodating misalignment, reducing vibration, and protecting both the motor and the driven machinery from excessive wear. In Will County lots of industries deploy AC or DC motors for various uses.

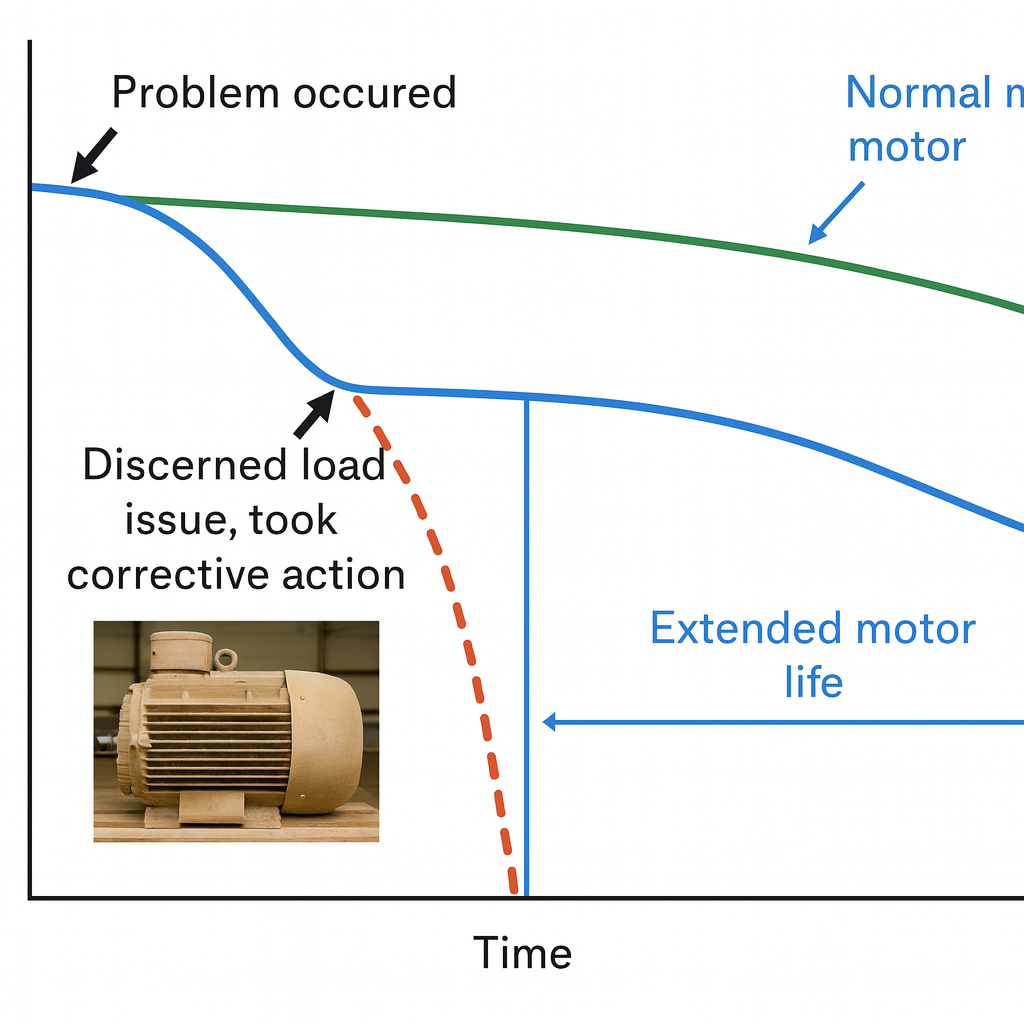

A well-selected and properly aligned coupling can:

- Extend motor life

- Improve system efficiency

- Minimize downtime

- Reduce maintenance costs

Types of Motor Couplings at TGEP LLC we Install and Service

At our company, we specialize in the installation and servicing of all major types of motor couplings, including:

🔹 Sure-Flex Couplings

Flexible and easy to install, Sure-Flex couplings are ideal for applications where misalignment and shock loads are common. Their elastomeric design helps dampen vibration and noise.

🔹 Gear Couplings

Known for their high torque capacity and durability, gear couplings are perfect for heavy-duty applications. They consist of two hubs with external gear teeth and a sleeve with internal teeth.

🔹 Chain Couplings

These couplings use a roller chain and sprockets to transmit torque. They are rugged and reliable, often used in conveyor systems and other industrial machinery.

🔹 Grid Couplings

Grid couplings offer excellent vibration damping and shock absorption. Their unique grid spring design makes them suitable for high-speed and high-torque applications.

The Importance of Proper Coupling Selection and Alignment

Choosing the right coupling isn’t just about matching torque ratings — it’s about understanding the application. Factors like misalignment tolerance, operating speed, environmental conditions, and load characteristics all influence the best choice.

Equally important is precision alignment. Misaligned couplings can lead to:

- Increased vibration

- Premature bearing and seal failure

- Excessive energy consumption

Using laser alignment tools and expert techniques, we ensure every coupling is installed to exact specifications, maximizing performance and longevity.

Couplings in Conveyor Systems

In conveyor systems, motor couplings play a pivotal role in ensuring smooth and efficient material handling. Whether it’s a belt conveyor in a packaging line or a screw conveyor in a grain processing plant, the right coupling ensures consistent motion and minimal mechanical stress.

Final Thoughts

The art of motor coupling lies in the balance between power transmission and mechanical harmony. We at TGEP try find the right coupling for the application, With the right coupling, properly installed and aligned, electric motors can deliver peak performance while minimizing wear and tear on connected equipment.

Whether you’re upgrading your system or troubleshooting vibration issues, our team is here to help with expert advice and hands-on service for all major coupling types.